Why does a better inventory forecast increase profits? Simply put, poor demand forecasting = higher carrying costs.

Problems with infrequent inventory forecasts:

- Flawed data that leads them expect a spike in demand when it isn’t necessarily there.

- Broad guesswork with inventory numbers creating false assumptions.

- Overlooking a profit trap due to needy resellers that take up more time than they’re worth.

An accurate demand forecast means you know you will have enough product on hand. Additionally, you avoid wasting valuable warehouse space on products that move more slowly. Find your par level using the inventory forecasts offered in our ecommerce accounting services. Or, use the 7 tips below to build a better inventory forecast.

How to forecast inventory

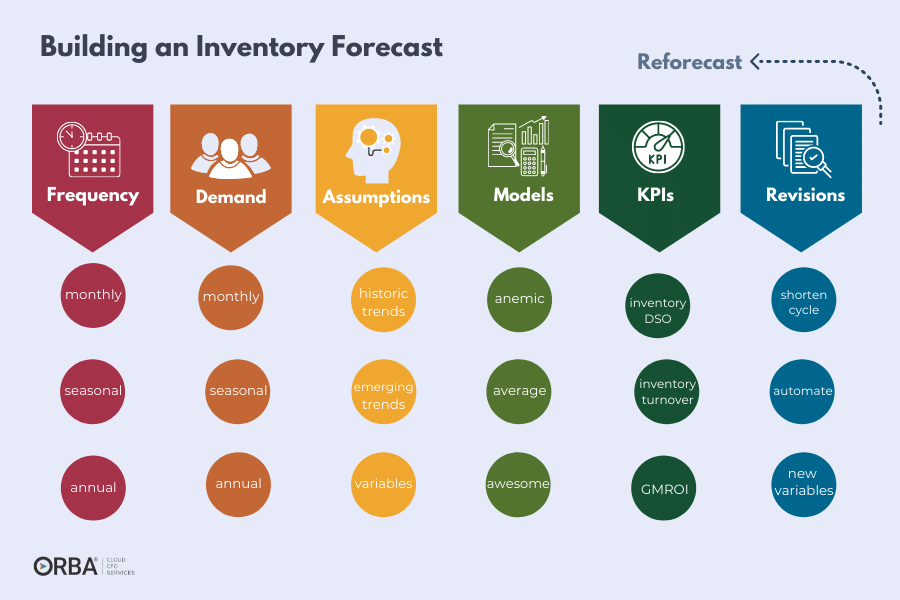

First, consider these factors when inventory forecasting:

- Frequency: Set forecast period (monthly, seasonally or annually)

- Review Demand: Look at historical demand by period

- Assumptions: Include variables and emerging trends

- Models: Run multiple scenarios (the 3 A’s: anemic, average, awesome!)

- KPIs: track relevant inventory KPIs

- Revise: Do you need to shorten your cycle? Automate? Include new variables?

- Reforecast

How to build a better inventory forecast

Next, avoid some common oversights and use these 7 tips to build a better inventory forecast:

1). Consider the best forecast period for your inventory

Standard forecasting intervals may include:

- Monthly inventory forecast

- Quarterly or seasonal inventory forecast

- Annual inventory forecast

Finding your sweet spot for timing may take a little trial and error but we always suggest running inventory forecasts more often. Monthly, for example. To reduce inventory costs add in seasonal forecasts however it makes sense for your business.

2). Understand expected demand by SKU, channel and location

Using the same frequency as above, review demand on a monthly, seasonal and annual basis.

To help prevent stockouts you should run inventory forecasting to include your expected demand by SKU. One way to forecast for expected demand is to create a massive spreadsheet and have your sales team give best guesses for what will sell the best and the fastest. This, as you might imagine, becomes cumbersome, subjective and time consuming as you scale. Alternatively, a robust system like NetSuite, its built-in Supply and Demand Planning Module coupled with our NetSuite accounting services can offer these forecasts on a regular basis.

Look at inventory at the SKU level and sales channel… is it coming from Nordstrom, a retailer, your website, or another reseller?

This becomes especially important for any ecommerce shop that uses third-party logistics (3PL) providers. For example, another company has warehouse space, so your product is sent straight there. That way you don’t have to have your own. Orders come through your website, then go straight to the 3PL provider to fulfill and ship orders. This is a great way to lower your landed cost.

Some use multiple 3PL locations to fulfill from different parts of the country or world, so managing and forecasting inventory by location becomes even more important. Having this information is key to make sure you’re only restocking the warehouses that are forecast to have high inventory turnover for that location.

3). Include both historical and emerging trends

Use assumptions made on both expected and emerging trends. But, be sure to include variables specific to your industry.

Ensure you have up-to-date margins on each product to understand how each contributes to profitability. By looking at past performance of a marketing campaign, your inventory team can ensure there is enough product on hand to meet customer demand, while simultaneously trying to cut costs. This approach to inventory forecasting can make a big impact on growth KPIs like profit margins.

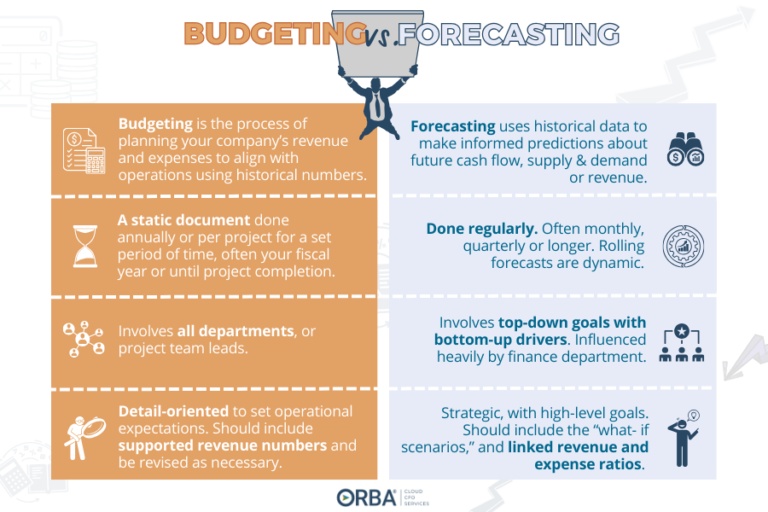

4). Run inventory models for different scenarios

When making financial projections, don’t forget to include the “what-if” scenarios. You want to prepare for the risk that you might miss your targets. Then you know how to shift procurement. That’s why we like to include models for anemic, average and awesome forecasts.

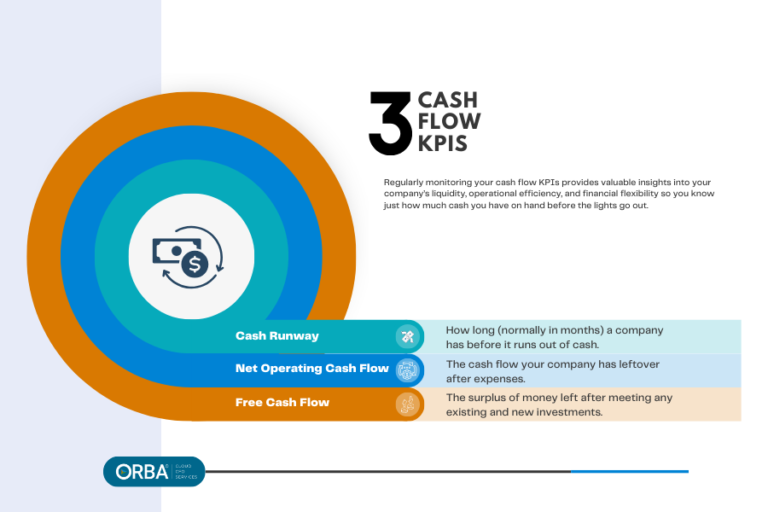

5). Track the GMROI Metric

One of my favorite supply chain kpis for inventory forecasting is the Gross Margin Return on Investment (GMROI). The GMROI provides insight into which inventory items are your best performers and worst sellers. The GMROI formula is:

GMROI = Gross profit/ Average inventory cost x 100

The higher the number the better, so you want to maximize it by keeping lower average inventory cost. Ideally you have a GMROI of 300-500%. If the ratio is below 100% that’s considered very bad. Using this ratio, you can identify your best and worst-case scenarios:

- Worst case scenario: you are selling products with very low profit margin and you’re just sitting on that inventory.

- Best case scenario: you are carrying product that is selling with a very high profit margin, and you’ve got just enough on-hand to fulfill your sales.

Related Read: To round out your inventory forecasting be sure to track all the top supply chain KPIs, like inventory DSO and inventory turnover.

6). Review your inventory forecast frequently.

Do you need to shorten your cycle? Automate? Include new variables? The longer your inventory forecast period, the less accurate the forecast becomes. This is due to fluctuations in the market, current events and risk. It’s easier to do this more frequently with a system like NetSuite that helps automate these tasks.

Cloud CFO Tip: For better inventory forecasting and management, an annual forecast should include seasonal fluctuations.

7). Reforecast

Once you have landed on the frequency of your forecasts then revisit and recreate them as needed. The companies that do this on a frequent basis are always better prepared to scale.

Need more tips for better inventory forecasting and management? Get in touch to learn more about our outsourced accounting services.